Harbor Research is conducting a webinar in partnership with Rockwell Automation that will focus on emerging digital applications and use cases to provide perspective on new industrial innovations. The webinar and related report explore the challenges and success factors that manufacturing organizations must consider, and provides executives with a framework for identifying new digital and Industrial Internet of Things (IIoT) solution opportunities.

MACHINE DATA DRIVES INNOVATION

The worlds of sensors, automation, machine learning, computing and communications are each changing rapidly, while at the same time converging into an entirely new era of digital innovation. As network, software and digital technologies continue to invade the physical world of sensors, machines and manufacturing, leadership in many industrial organizations is recognizing the significant value created from extracting and leveraging the machine data and usage information from their equipment, systems and organizations.

As organizations become more “digitally mature,” new manufacturing and process innovations will be self-organized by people and companies who are motivated to explore and develop innovative operating models. Collaborative innovation will extend beyond just ideas about producing products to the very manner in which business is conducted.

Source: Harbor Research, Inc.

Today, mission-critical industries including manufacturing, utilities, oil & gas and mining are all being disrupted by digital and IIoT technologies. Incumbents are quickly realizing that in order to address this wave of digital innovation, they will have to completely re-think how technology will impact their operations.

DISCOVERING DIGITAL INNOVATION OPPORTUNITIES

New digital and IIoT technologies are driving a multi-year wave of innovations based on the convergence of embedded software, machine intelligence and networked data collection and analytics. Inside such systems, reliable and blindingly fast microprocessors do what they are very good at doing (and what people are very bad at doing): digesting billions of data-points, talking to each other about the data, controlling each other based upon the state of the data. All in a matter of nanoseconds.

Human beings cannot do this, nor should they; this incessant stream of ongoing business information should be “invisible” to people. At the same time, all this invisible machine activity makes the state of (i.e., the information about) a business’s assets, costs, and liabilities vastly more visible to managers and to the decision-making process—when decision-makers need or want to know.

Source: Harbor Research, Inc.

If you applied this vision in a practical way to business, it might simply be called “automation.” But we don’t mean the automation of just machines and equipment. We have that today. Instead, such systems will open an entirely new portfolio of “killer apps” that will transform the way business is done across the industrial landscape, and profoundly improve customer satisfaction, operating costs, flexibility and more.

UNDERSTANDING INDUSTRIAL DIGITAL APPLICATIONS & USE CASES

Digital innovation is not just about the dichotomy between people communicating with people or machines communicating with machines. It also includes people communicating with machines (e.g., a networked robot) and machines communicating with people (e.g., automated work instructions). Digital and IIoT innovations’ most profound potential lies in their ability to connect diverse smart sensors, machines and equipment into more intelligent, aware and adaptive systems that will enable a whole new generation of manufacturing capabilities.

Source: Harbor Research, Inc.

Digital innovation is driven by networks, software, data and analytics enabling the integration and exchange of machine, operations and business data to generate insight and achieve performance-driven outcomes. Asset, process and production systems data is collected and combined with business system data to diagnose, predict, prevent and optimize equipment, processes and events associated with manufacturing operations.

New digital and IIoT technology and solutions will revolve around real-time situational awareness and automated analysis. Technology moves beyond just proposing task solutions—such as executing a work order or a sales order—to sensing what is happening in the world around it, analyzing that new information for risks and possibilities, presenting alternatives, and taking actions.

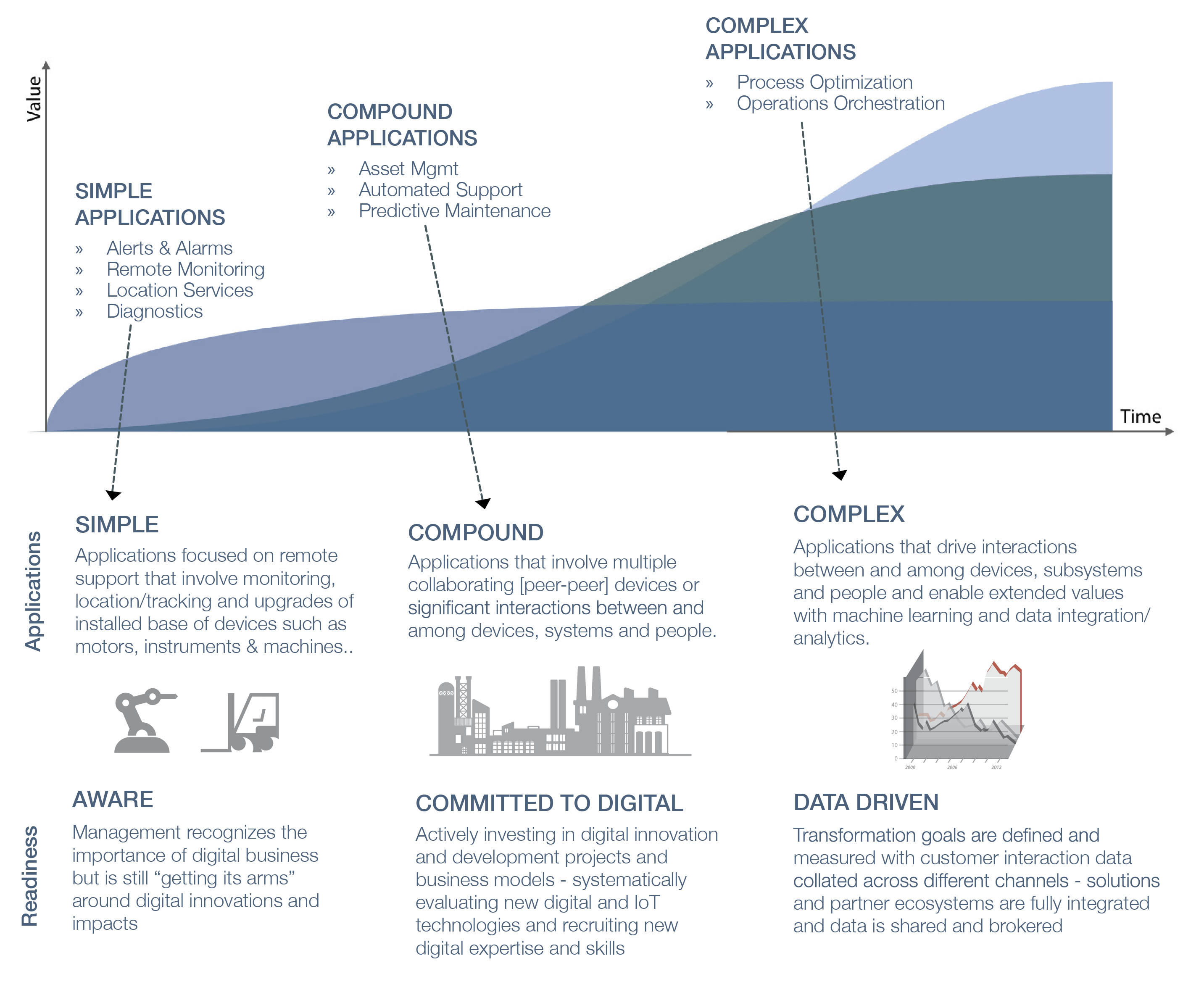

As technologies mature and standards become the norm, applications based on deeper, peer-to-peer interactions between devices, systems and people will drive more dynamic value streams. This opens up new collaborative solution opportunities that have the potential to drive much greater value.

SETTING PRIORITIES, STAGING RESOURCES & ORGANIZING TO ACT

The strategies and organizational approaches adopted by many manufacturers today reflect their internal culture and long-held beliefs. This often inhibits teams and individuals in their pursuit of new innovations and solutions. Manufacturers need to move beyond their “comfort zone” and focus on developing skills and capabilities that expand an organization’s ability to evolve their core operating practices and leverage a more flexible mix of new approaches—determining the best mix and the most viable paths for developing new solution opportunities.

Management teams will need to make decisions in two distinct contexts—running their core business as efficiently as possible while also being able to identify new manufacturing and systems innovations to invest in and deploy. We have entered a new chapter where non-traditional innovation practices will become more common.

When traditional business practices, company culture and operating models inhibit the required creativity and speed to effectively drive new customer innovation and value creation, or when traditional operating models constrain the organization’s ability to develop new technical skills or organizational capabilities, manufacturers need to seriously consider alternative innovation modes and non-traditional collaboration processes.

Problem solving for new digital innovation and solution opportunities must address tough questions: How can an organization turns its workers, partners and customers into believers and contributors to digital innovation? How can we find new ways to collaborate that can impact multiple functions and core operations and ultimately solve really big challenges and create unique new manufacturing solutions?

This essay is supported by our exclusive Rockwell-commissioned report on the 90 use cases leading transformation in IIoT.

Fill out the form below to download this 50-page report for free.